- +86 13837949030 +86 15890619536

- info@lymcbearings.com export@lymcbearings.com

- Luoxin Industrial Cluster, Luoyang City,Henan Province,China

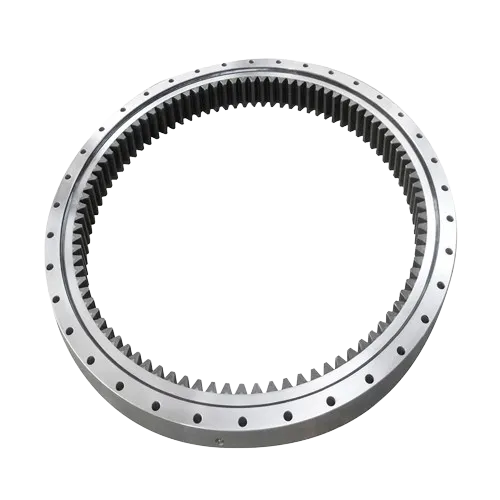

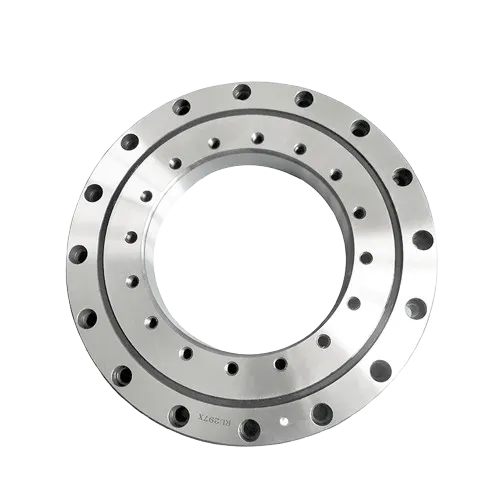

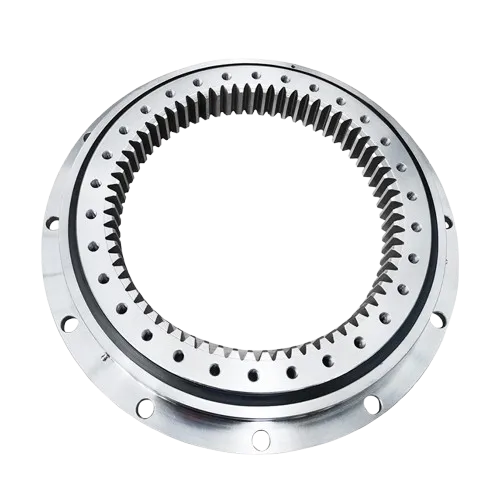

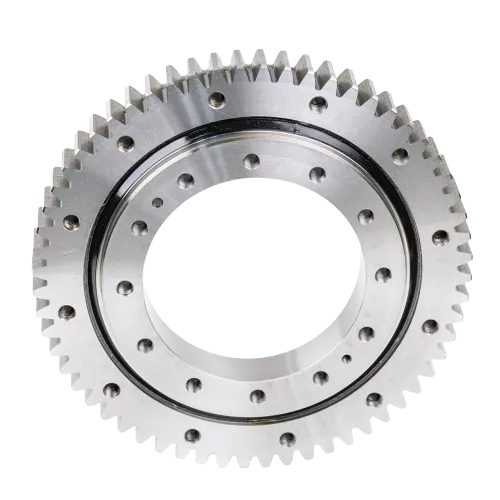

These are the main components that provide the structural integrity and the primary load-bearing capacity of the bearing. The rings have mounting holes for easy installation and can be either toothed or smooth.

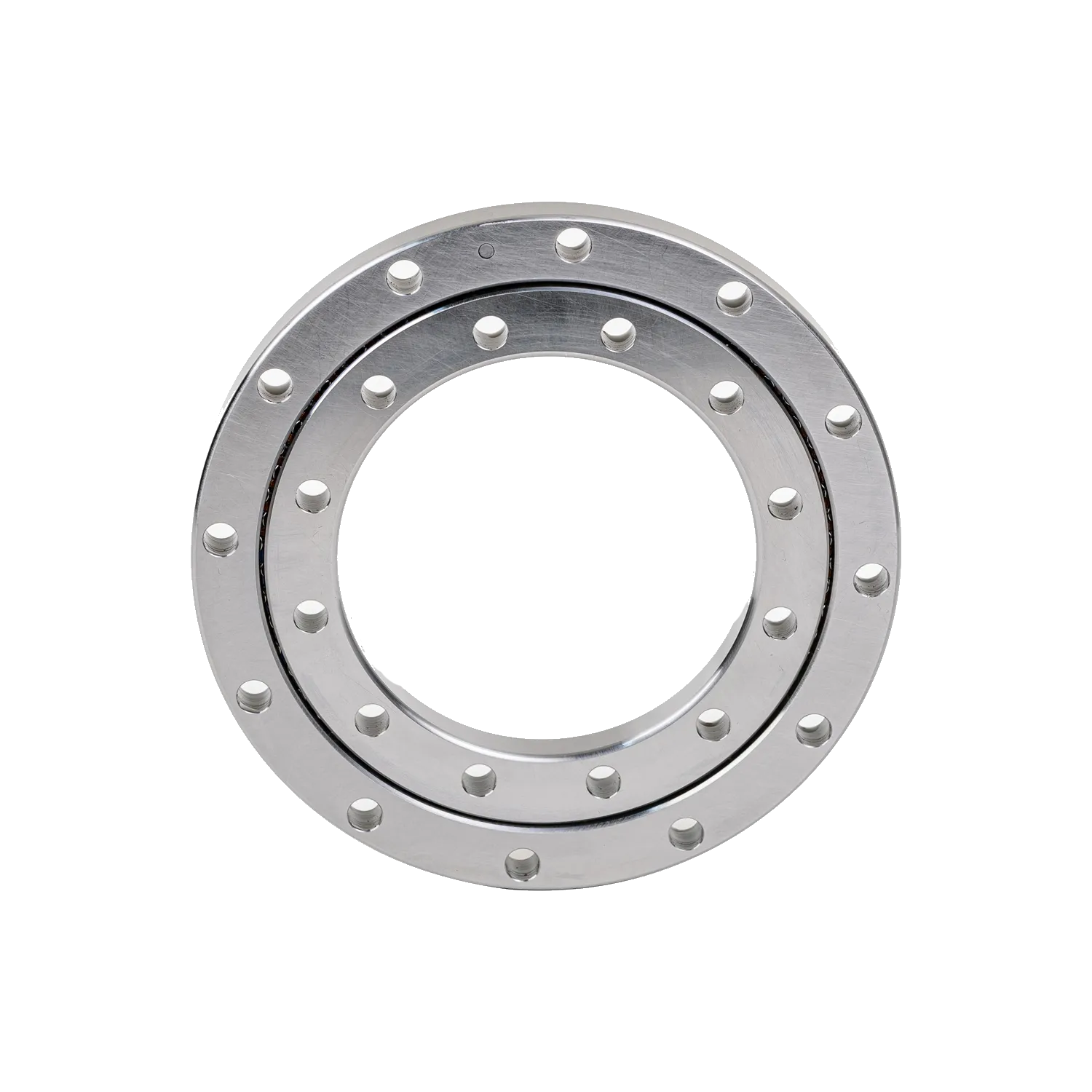

Balls or rollers placed between the rings to reduce friction and facilitate smooth rotation. The rolling elements are contained within a cage or spacer system to maintain even spacing and prevent contact.

To protect the bearing from contaminants like dirt, dust, and moisture, seals are used on both sides of the bearing.

Lubricants (grease or oil) are crucial for reducing friction and wear between the rolling elements and raceways. Some slewing bearings come pre-lubricated, while others require periodic lubrication maintenance.

Static Load Capacity: The maximum load a bearing can withstand without permanent deformation.

Dynamic Load Capacity: The maximum load a bearing can endure while rotating or oscillating.

Bearings should exhibit minimal deflection under load to ensure accurate positioning and smooth operation.

Bearings must be able to operate at the required speeds for the application without excessive heat generation or wear.

High precision and tight tolerances are essential for applications requiring accurate positioning and smooth rotation.

Proper lubrication reduces friction, wear, and overheating, extending the bearing's lifespan. Both grease and oil lubrication are common, depending on the application.

Effective seals protect the bearing from contaminants such as dust, dirt, and moisture, which can lead to premature failure.

The material and heat treatment process of the bearing components (rings and rolling elements) determine their hardness, wear resistance, and fatigue life.

Correct mounting and installation are crucial to bearing performance. Misalignment, improper torqueing of bolts, and uneven load distribution can all negatively impact performance.

Regular maintenance, including inspection and relubrication, is necessary to detect and address issues before they lead to failure. Condition monitoring systems can provide early warnings of potential problems.

Operating conditions such as temperature, humidity, and exposure to corrosive elements can affect bearing performance. Bearings designed for specific environments (e.g., marine, high-temperature) should be used accordingly.

Quality Service For Industry Projects And Automative Service

Consult Us Now