Introduction:

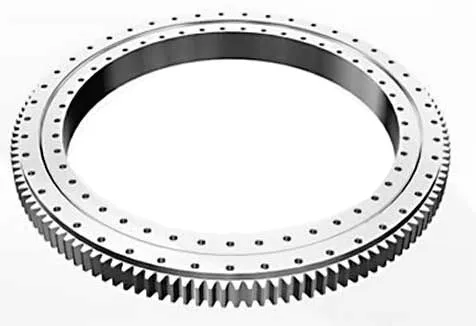

Crossed roller bearings are a type of anti-friction rolling element bearing that is widely used in various industries due to their unique design and capabilities. Among the different series available, the CRBH series stands out for its exceptional performance and versatility. In this article, we will explore the features, advantages, and common application fields of the CRBH series crossed roller bearings.

Advantages:

1. Precise and Rigidity: The CRBH series crossed roller bearings offer high precision and rigidity, making them suitable for applications that require accurate positioning and minimal deflection under heavy loads.

2. Compact Design: These bearings are designed with a compact structure, allowing them to be used in limited space environments without compromising performance.

3. High Load Capacity: The crossed roller design enables CRBH series bearings to support high axial, radial, and moment loads simultaneously, making them ideal for applications that require robust load handling capabilities.

4. Low Friction and Wear: The unique roller arrangement minimizes friction and wear, resulting in reduced energy consumption and extended service life.

5. Easy Installation and Maintenance: The simple construction of CRBH series crossed roller bearings allows for easy installation, adjustment, and maintenance, reducing downtime and overall operating costs.

Common Application Fields:

1. Robotics and Automation: Crossed roller bearings in the CRBH series are extensively used in robotics and automation systems, where precise movement and high rigidity are crucial for achieving accurate and reliable performance.

2. Machine Tools: These bearings are commonly employed in machine tools such as milling machines, lathe spindles, and grinding machines. Their high load capacity and rigidity make them ideal for supporting heavy machining operations.

3. Medical Equipment: The compact design and high precision of CRBH series crossed roller bearings make them suitable for medical equipment applications such as surgical robots, CT scanners, and X-ray machines.

4. Industrial Machinery: Various industrial machinery, such as printing machines, packaging equipment, and conveyors, benefit from the exceptional load handling capabilities and compact design of CRBH series bearings.

5. Aerospace and Defense: Crossed roller bearings are utilized in aerospace and defense applications due to their ability to withstand extreme conditions, high loads, and precise movements required in aircraft landing gear systems, radar systems, and satellite antennas.

Conclusion:

The CRBH series crossed roller bearings offer exceptional performance, high precision, and robust load handling capabilities for a wide range of applications. Their advantages, including compact design, low friction, and easy maintenance, make them an ideal choice in industries such as robotics, machine tools, medical equipment, industrial machinery, and aerospace and defense. By understanding the benefits and common fields of application, users can leverage the CRBH series to improve equipment performance and reliability.

Serie CRBH

|

Diámetro del eje

|

Identificación

|

Dimensiones principales

|

Dimensiones de montaje (mm)

|

Clasificación básica de carga dinámica

|

Clasificación de carga estática básica

|

|

|

(mm)

|

Peso

|

Anillo interior

|

Diámetro exterior

|

Ancho

|

Chaflán

|

da

|

Da

|

C

|

Co

|

(Kg)

|

|

r

|

(N)

|

(N)

|

|

(mm)

|

d

|

D

|

B

|

(min)

|

|

|

|

20

|

CRBH208A

|

CRBH208AUU

|

20

|

36

|

8

|

0.3

|

24

|

31

|

2910

|

2430

|

0.04

|

|

25

|

CRBH258A

|

CRBH258AUU

|

25

|

41

|

8

|

0.3

|

29

|

36

|

3120

|

2810

|

0.05

|

|

30

|

CRBH3010A

|

CRBH3010AUU

|

30

|

55

|

10

|

0.3

|

36.5

|

48.5

|

7600

|

8370

|

0.12

|

|

35

|

CRBH3510A

|

CRBH3510AUU

|

35

|

60

|

10

|

0.3

|

41.5

|

53.5

|

7900

|

9130

|

0.13

|

|

40

|

CRBH4010A

|

CRBH4010AUU

|

40

|

65

|

10

|

0.3

|

46.5

|

58.5

|

8610

|

10600

|

0.15

|

|

45

|

CRBH4510A

|

CRBH4510AUU

|

45

|

70

|

10

|

0.3

|

51.5

|

63.5

|

8860

|

11300

|

0.16

|

|

50

|

CRBH5013A

|

CRBH5013AUU

|

50

|

80

|

13

|

0.6

|

56

|

74

|

17.3

|

20.9

|

0.29

|

|

60

|

CRBH6013A

|

CRBH6013AUU

|

60

|

90

|

13

|

0.6

|

66

|

84

|

18.8

|

24.3

|

0.33

|

|

70

|

CRBH7013A

|

CRBH7013AUU

|

70

|

100

|

13

|

0.6

|

76

|

94

|

20.1

|

27.7

|

0.38

|

|

80

|

CRBH8016A

|

CRBH8016AUU

|

80

|

120

|

16

|

0.6

|

88

|

112

|

32.1

|

43.4

|

0.74

|

|

90

|

CRBH9016A

|

CRBH9016AUU

|

90

|

130

|

16

|

0.6

|

98

|

122

|

33.1

|

46.8

|

0.81

|

|

100

|

CRBH10020A

|

CRBH10020AUU

|

100

|

150

|

20

|

0.6

|

110

|

140

|

50.9

|

72.2

|

1.45

|

|

110

|

CRBH11020A

|

CRBH11020AUU

|

110

|

160

|

20

|

0.6

|

120

|

150

|

52.4

|

77.4

|

1.56

|

|

120

|

CRBH12025A

|

CRBH12025AUU

|

120

|

180

|

25

|

1

|

132

|

168

|

73.4

|

108

|

2.62

|

|

130

|

CRBH13025A

|

CRBH13025AUU

|

130

|

190

|

25

|

1

|

142

|

178

|

75.9

|

115

|

2.82

|

|

140

|

CRBH14025A

|

CRBH14025AUU

|

140

|

200

|

25

|

1

|

152

|

188

|

81.9

|

130

|

2.96

|

|

150

|

CRBH15025A

|

CRBH15025AUU

|

150

|

210

|

25

|

1

|

162

|

198

|

84.3

|

138

|

3.16

|

|

200

|

CRBH20025A

|

CRBH20025AUU

|

200

|

260

|

25

|

1

|

212

|

248

|

92.3

|

169

|

4

|

|

250

|

CRBH25025A

|

CRBH25025AUU

|

250

|

310

|

25

|

1.5

|

262

|

298

|

102

|

207

|

4.97

|