- +86 13837949030 +86 15890619536

- info@lymcbearings.com export@lymcbearings.com

- Luoxin Industrial Cluster, Luoyang City,Henan Province,China

Gear Racks are a type of linear gear used to convert rotational motion into linear motion. They are an essential component in many mechanical systems, providing a way to translate the rotational movement of a pinion gear into a straight-line motion.When designing or selecting a gear rack and pinion system, factors such as load capacity, speed, alignment, material, and the required precision of motion need to be considered. Proper lubrication and alignment are crucial for efficient operation and to minimize wear and tear. Gear racks have teeth that are cut in a straight line along their length. The teeth are typically designed to mesh with the pinion gear, which has a matching circular tooth profile.

A gear rack is a type of linear gear used in combination with a cylindrical gear known as a pinion. Together, the pinion and gear rack convert rotational motion into linear motion, or vice versa. Here’s a more detailed introduction:

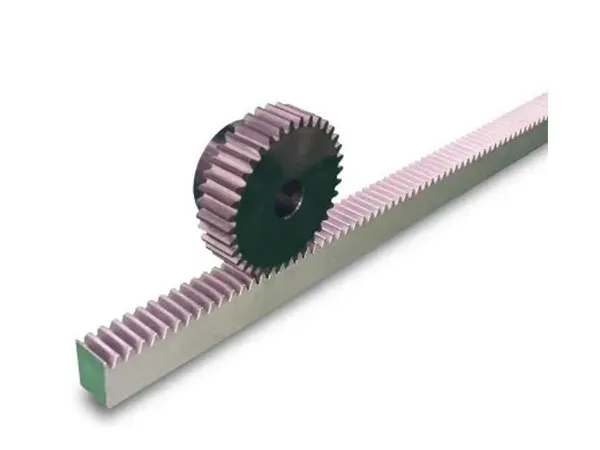

Gear Rack: It is a straight or flat bar with teeth cut into it that match the teeth of a pinion gear. The rack is essentially a segment of a gear with an infinite radius.

Pinion Gear: A circular gear that engages with the gear rack. When the pinion rotates, it moves along the length of the rack, thus creating linear motion.

Straight Tooth Gear Racks: Have teeth that are cut parallel to the length of the rack. These are simple and widely used for general purposes.

Helical Gear Racks: Have angled teeth that engage more gradually, providing smoother and quieter motion. They are used where noise reduction is important or when a higher load capacity is needed.

Gear racks are used in various applications where linear motion is required, such as:

Railways: Used in rack railways for steep gradient tracks.

Steering Systems: In automotive steering systems (rack and pinion steering).

Machine Tools: CNC machines use gear racks for precise linear motion.

Lifts and Elevators: For the movement of platforms and cabins.

Automation and Robotics: In linear actuators and motion control systems.

Simple Mechanism: Provides a straightforward way to convert rotational to linear motion.

High Efficiency: Especially useful for transmitting power over a short distance.

Cost-Effective: Easier to design and manufacture compared to other systems for linear motion.

Considerations in Design

When designing or selecting a gear rack and pinion system, factors such as load capacity, speed, alignment, material, and the required precision of motion need to be considered. Proper lubrication and alignment are crucial for efficient operation and to minimize wear and tear.