- +86 13837949030 +86 15890619536

- info@lymcbearings.com export@lymcbearings.com

- Luoxin Industrial Cluster, Luoyang City,Henan Province,China

Time:2025-04-23 08:44:22 Source:Luoyang MC Bearing Technology Co.,Ltd.

Adjusting the clearance of a slewing bearing is crucial for ensuring smooth operation, reducing wear, and extending its service life. The process varies depending on the bearing type (single-row ball, double-row ball, or cross-roller) and the manufacturer's specifications.

Before adjusting the slewing bearing clearance, it’s important to assess the condition of the bearing and machinery:

Inspect the Bearing: Look for signs of wear, damage, or corrosion. If the bearing is significantly worn or damaged, it may require replacement.

Check Manufacturer Specifications: Ensure you know the recommended clearance values provided by the bearing manufacturer. These values are essential for setting the correct adjustment.

To adjust slewing bearing clearance, you will need the following tools:

Dial indicator or laser measurement tool

Feeler gauges

Torque wrench

Shims or spacers (if applicable)

Jack (if lifting the structure is necessary)

Lubrication (specific grease or oil for the bearing)

Before making any adjustments, it is important to measure the current clearance. This will help determine whether the bearing is within the desired tolerance or if adjustments are needed.

Axial Clearance:

Place a dial indicator perpendicular to the raceway.

Lift the upper structure (if applicable) slightly using a jack or lifting mechanism.

Measure the axial movement along the bearing's axis.

Radial Clearance:

Attach the dial indicator parallel to the bearing’s radial surface.

Apply side force to the structure to check the movement in the radial direction.

Tilting Clearance:

Measure the angular clearance by placing the dial indicator at multiple points along the bearing. Check for any tilting or angular movement.

Record the measurements and compare them with the specifications. If the clearance is out of the acceptable range, proceed to adjustment.

The adjustment process will vary depending on the bearing design. There are two main types of slewing bearings: adjustable bolt-type and gear-type.

For Adjustable Bolt-Type Bearings:

These bearings typically feature mounting bolts and spacers that can be adjusted to modify the clearance.

Loosen the Mounting Bolts: Gradually loosen the bolts securing the bearing in place. Do this in a crisscross pattern to avoid uneven stress.

Adjust the Clearance:

If the clearance is too tight, you can insert shims or spacers between the bearing races to increase the gap.

If the clearance is too loose, you can remove shims or spacers to tighten the bearing.

Tighten the Bolts: Once the desired clearance is achieved, tighten the mounting bolts in a crisscross pattern to ensure even pressure distribution. Be careful not to overtighten.

Recheck the Clearance: After tightening the bolts, measure the clearance again to confirm that it falls within the specified range.

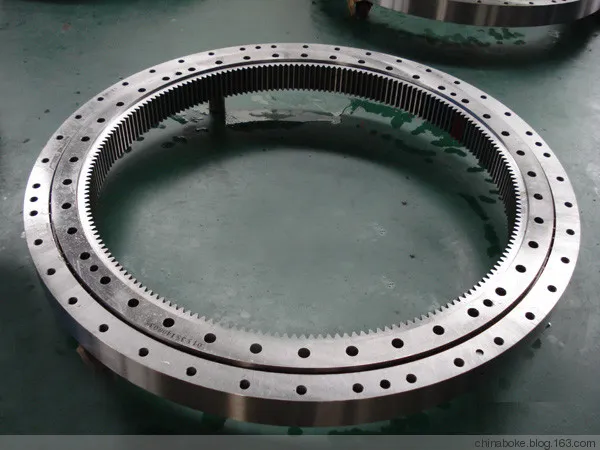

For Gear-Type Bearings:

These bearings use a pinion to mesh with the gear, and adjustments are usually made by modifying the backlash.

Adjust the Pinion Position: To change the clearance, adjust the pinion’s position relative to the gear.

Increase clearance by moving the pinion away slightly.

Decrease clearance by moving the pinion closer to the gear.

Check Backlash: Ensure the backlash between the gear and pinion is within the recommended range.

Recheck Clearance: After adjustment, verify the radial and axial clearance using measurement tools.

Once the adjustments have been made, rotate the slewing bearing manually to check for smooth operation. Ensure that the bearing turns freely without any binding, excessive play, or abnormal noises.

Check for Evenness: Rotate the bearing 360° and recheck the clearance at various points to ensure uniform adjustment.

Lubricate the Bearing: Apply fresh, manufacturer-recommended grease or oil to the bearing to reduce friction and prevent wear.

Record the final clearance values and any modifications made during the adjustment. Regularly monitor the bearing’s performance during operation, checking for abnormal vibrations, excessive wear, or changes in clearance over time. Set up periodic inspections to ensure the bearing remains in optimal condition.

Conclusion

Adjusting slewing bearing clearance is a precise process that ensures the efficient and safe operation of machinery. By following these steps and utilizing the right tools and methods, you can maintain proper clearance, prevent premature wear, and extend the service life of the bearing. Always refer to the manufacturer’s guidelines to ensure that the adjustments are within acceptable tolerances.